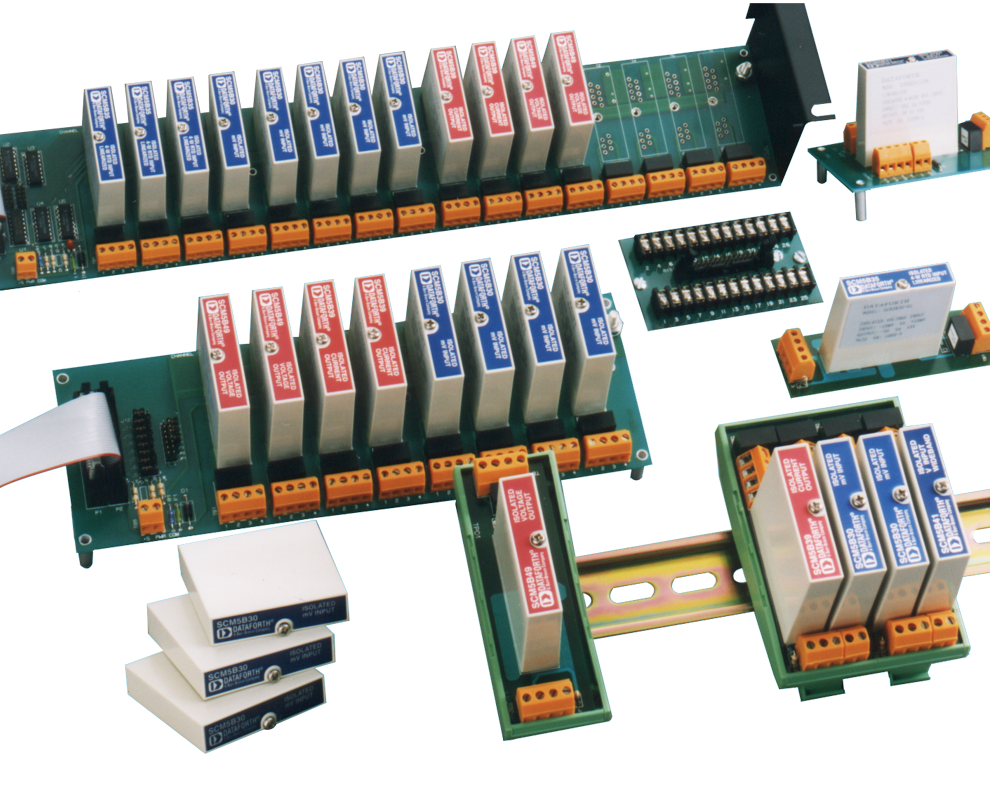

an802: DSCA, SCM5B, SCM7B and 8B Failure Rate Calculation and Prediction

Application Note

Failure rate calculations for the DSCA, SCM5B, SCM7B, and 8B modules are derived from MILHDBK-217F,

Reliability Prediction of Electronic Equipment.

The “Part Stress Analysis” method is used at a ground benign environment, +30°C temperature, and quality level B-2 to D-1 depending on the component. The specified humidity level is 95% RH noncondensing.

All DSCA, SCM5B, SCM7B, and 8B modules undergo a 48 hour burn-in at +85°C before final calibration and shipment. This “preconditioning” serves to minimize field failures by stabilizing components and causing “infant failures,” if any, to occur.

The failure rates presented below apply to modules under normal operating conditions.

The “Part Stress Analysis” method is used at a ground benign environment, +30°C temperature, and quality level B-2 to D-1 depending on the component. The specified humidity level is 95% RH noncondensing.

All DSCA, SCM5B, SCM7B, and 8B modules undergo a 48 hour burn-in at +85°C before final calibration and shipment. This “preconditioning” serves to minimize field failures by stabilizing components and causing “infant failures,” if any, to occur.

The failure rates presented below apply to modules under normal operating conditions.

DSCA Modules

SCM7B Modules and Accessories

SCM5B Modules and Accessories

8B Modules and Accessories

Was this content helpful?

Thank you for your feedback!